Shamsher Khan's Email & Phone Number

controls engineer at Tesla

Shamsher Khan Email Addresses

Shamsher Khan Phone Numbers

Shamsher Khan's Work Experience

Rave Energy

Partner and CTO

March 2020 to Present

Rave Travel Technology

Co-Founder and CMO

November 2018 to Present

Smurfit Kappa North America

Sr. Controls Engineer (Contract)

February 2016 to May 2017

Rave Engineering

Automation Consultant

September 2012 to January 2016

Contract Project for various Companies

Automation Consultant

September 2012 to January 2016

Siemens Energy and Automation

Product Engineer II

May 2007 to November 2009

Katecho

Machine Design Engineer

May 2006 to May 2007

Rave Energy

Partner

Show more

Show less

Shamsher Khan's Education

BAF Shaheen

High School

Oklahoma State University

Bachelor Of Science, Electrical Engineering

May 2024 to May 2024

Show more

Show less

Frequently Asked Questions about Shamsher Khan

What is Shamsher Khan email address?

Email Shamsher Khan at [email protected], [email protected] and [email protected]. This email is the most updated Shamsher Khan's email found in 2024.

What is Shamsher Khan phone number?

Shamsher Khan phone number is +1.9186290498, +1.8174942341, +1.8177043235 and +1.9187704523.

How to contact Shamsher Khan?

To contact Shamsher Khan send an email to [email protected], [email protected] or [email protected]. If you want to call Shamsher Khan try calling on +1.9186290498, +1.8174942341, +1.8177043235 and +1.9187704523.

What company does Shamsher Khan work for?

Shamsher Khan works for Tesla

What is Shamsher Khan's role at Tesla?

Shamsher Khan is Sr. Controls Project Manager

What industry does Shamsher Khan work in?

Shamsher Khan works in the Mining & Metals industry.

Shamsher Khan's Professional Skills Radar Chart

Based on our findings, Shamsher Khan is ...

What's on Shamsher Khan's mind?

Based on our findings, Shamsher Khan is ...

Shamsher Khan's Estimated Salary Range

Shamsher Khan Email Addresses

Shamsher Khan Phone Numbers

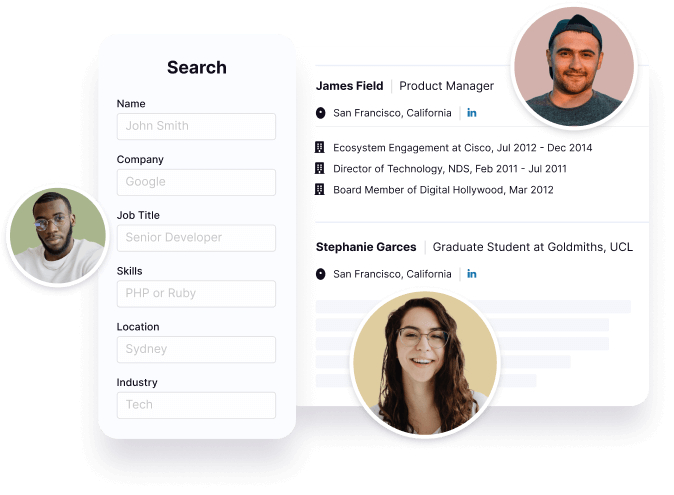

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Shamsher Khan's Personality Type

Introversion (I), Intuition (N), Thinking (T), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Shamsher Khan's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 90% chance that Shamsher Khan is seeking for new opportunities

Shamsher Khan's Social Media Links

/in/shamsher-khan-3ba40513 /school/oklahoma-state-university/ /company/raveenergy