Eliana Veloso's Email & Phone Number

Senior Process Engineer at Rosenberg WorleyParsons

Eliana Veloso Email Addresses

Eliana Veloso's Work Experience

Lead Process Engineer

Senior Process Engineer

SUPER OCTANOS

Process Engineer

VEPICA (Venezolana de Proyectos

Process Engineer

PROYECTOS MARFRAN

Process Engineer

Process Engineer

Show more

Show less

Eliana Veloso's Education

Universidad de Zaragoza

Postgraduate Degree in Design and Engineering of Industrial Fluid Installations Engineering 8.00/10

Universidad Metropolitana (VE)

Diploma in gas Engineering 19.00/20

Universidad de Oriente (VE)

Diploma Industrial Engineering 9.77/10

Universidad de Oriente (VE)

Bachelor's Degree Chemical engineering 8.20/10

Show more

Show less

Frequently Asked Questions about Eliana Veloso

What is Eliana Veloso email address?

Email Eliana Veloso at [email protected] and [email protected]. This email is the most updated Eliana Veloso's email found in 2024.

What is Eliana Veloso phone number?

Eliana Veloso phone number is +31686810712.

How to contact Eliana Veloso?

To contact Eliana Veloso send an email to [email protected] or [email protected]. If you want to call Eliana Veloso try calling on +31686810712.

What company does Eliana Veloso work for?

Eliana Veloso works for Rosenberg WorleyParsons

What is Eliana Veloso's role at Rosenberg WorleyParsons?

Eliana Veloso is Lead Process Engineer

What industry does Eliana Veloso work in?

Eliana Veloso works in the Oil & Energy industry.

Eliana Veloso's Professional Skills Radar Chart

Based on our findings, Eliana Veloso is ...

What's on Eliana Veloso's mind?

Based on our findings, Eliana Veloso is ...

Eliana Veloso's Estimated Salary Range

Eliana Veloso Email Addresses

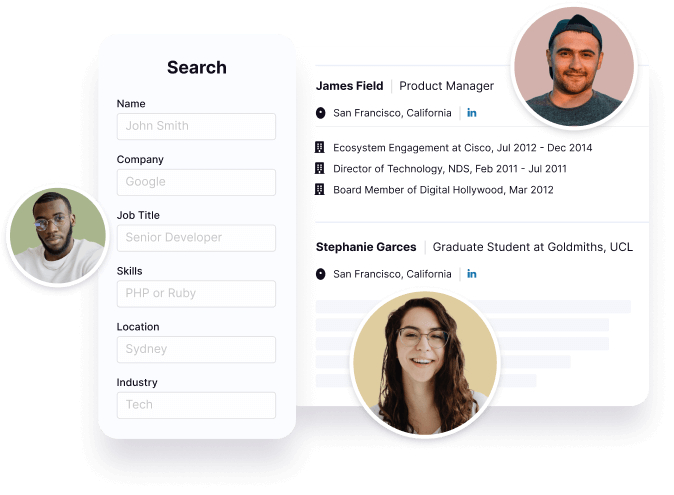

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Eliana Veloso's Personality Type

Introversion (I), Intuition (N), Thinking (T), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Eliana Veloso's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 93% chance that Eliana Veloso is seeking for new opportunities

Eliana Veloso's Social Media Links

/in/eliana-veloso-franco-b8958717