Peter Kent's Email & Phone Number

Stunt double

Peter Kent's Email Addresses

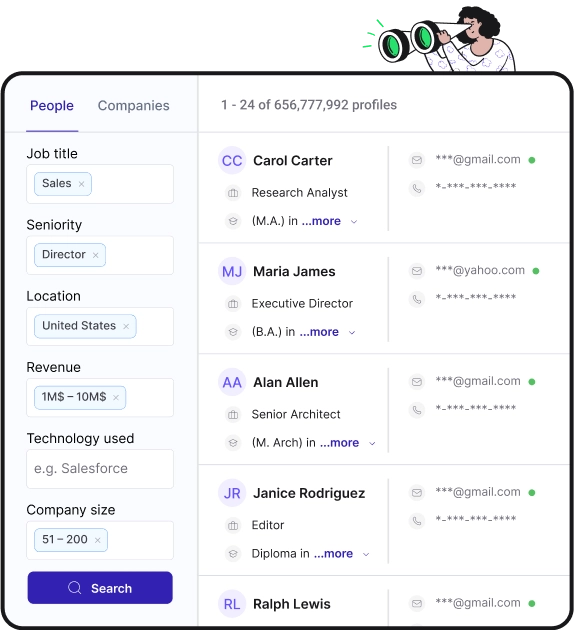

Find personal and work emails for over 300M professionals

Not the Peter Kent you were looking for? Continue your search below:About Peter Kent

📖 Summary

Peter Kent is a renowned stunt double who has made a name for himself in the world of Hollywood action films. With his impressive physique and fearless attitude, Peter has performed stunts for some of the biggest stars in the industry, including Arnold Schwarzenegger and Sylvester Stallone. His career has spanned over four decades, and he has worked on over 150 films, making him a true legend in the world of stunts.

Peter Kent's journey to becoming a stunt double began in his early 20s when he found himself working as a bodybuilder. His impressive physique and athleticism caught the eye of filmmakers, and he was soon offered the opportunity to work as a stunt double. Peter's first major break came when he was cast as the body double for Arnold Schwarzenegger in the 1984 film "The Terminator." The role required him to perform a wide range of dangerous stunts, including high falls, car chases, and hand-to-hand combat. Peter's dedication and fearlessness impressed the film's director, James Cameron, and set the stage for what would become a remarkable career in the world of stunts.

Throughout his career, Peter Kent has worked on a wide range of film genres, from action-packed blockbusters to gritty dramas. He has performed stunts for some of the biggest names in the industry, including Sylvester Stallone, Jean-Claude Van Damme, and Steven Seagal. His work has taken him all over the world, from the bustling streets of Los Angeles to the remote jungles of South America. Peter's willingness to take on any challenge and his unwavering commitment to safety have made him a highly sought-after stunt double in the industry.

One of the most iconic roles Peter Kent is known for is his work as the stunt double for Arnold Schwarzenegger in the "Terminator" series. His fearless portrayal of the Terminator in high-stakes action sequences earned him a reputation as one of the best stunt doubles in the business. Peter's work on the "Terminator" films pushed the boundaries of what was possible in stunt work, with jaw-dropping stunts that left audiences on the edge of their seats. His work on the "Terminator" series solidified his status as a legend in the world of stunt performers and set a new standard for action-packed filmmaking.

In addition to his work in film, Peter Kent has also lent his expertise to the world of television. He has performed stunts on hit shows such as "The A-Team," "MacGyver," and "Buffy the Vampire Slayer," bringing his unique blend of athleticism and fearlessness to the small screen. His work in television has earned him a dedicated fan base and has further solidified his reputation as one of the best in the business.

As a veteran in the world of stunts, Peter Kent has seen the industry evolve and change over the years. He has witnessed the introduction of new technology and techniques that have elevated the art of stunt work to new heights. Despite these advancements, Peter remains committed to the traditional values of stunt performing, placing a strong emphasis on safety and precision in his work. His dedication to his craft and his willingness to push the boundaries of what is possible in stunt work have made him a mentor and role model to up-and-coming stunt performers.

Beyond his work on the big and small screen, Peter Kent is also an advocate for the welfare of stunt performers. He has been a vocal proponent for better safety standards and working conditions for stunt workers, using his platform to raise awareness and push for positive change in the industry. His dedication to the well-being of his fellow stunt performers has earned him the respect and admiration of his peers and has solidified his legacy as a true trailblazer in the world of stunts.

In a career that spans over four decades, Peter Kent has established himself as one of the most respected and revered stunt performers in the industry. His fearless approach to his work, his unwavering commitment to safety, and his impressive list of credits have made him a true icon in the world of Hollywood action films. Whether he's jumping from rooftops, engaging in intense fight scenes, or performing death-defying stunts, Peter Kent continues to push the boundaries of what is possible in the world of stunt performing, leaving a lasting legacy that will continue to inspire generations of stunt performers to come.

Frequently Asked Questions about Peter Kent

Who was Arnold Schwarzenegger stunt double?

Peter Kent of Qualicum Beach was a stunt double for Arnold Schwarzenegger for 15 years. As you can imagine, he was tossed around, run over, and beat up - a lot. He talks with Host Peter McCully about his adventures as a stunt man, life with Arnold, and life after Arnold.Mar 9, 2022

Peter Kent's Email Addresses

People you may be

interested in

Football wide receiver

American actress

Canadian actress

Writer

American actress

Canadian physician

American writer

American actor

American singer and TV personality

Turkish writer and journalist

American actress

American comedian and actress