Michael Abraham's Email & Phone Number

Farrah Abraham's father

Michael Abraham's Email Addresses

Michael Abraham's Phone Numbers

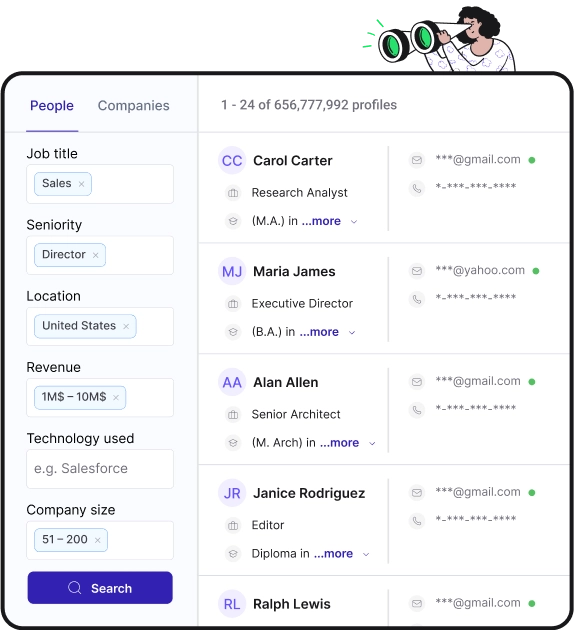

Find personal and work emails for over 300M professionals

Not the Michael Abraham you were looking for? Continue your search below:About Michael Abraham

📖 Summary

Michael Abraham is best known for being the father of reality TV star Farrah Abraham. Michael Abraham has made several appearances on his daughter's reality show "Teen Mom" and has garnered attention for his supportive and sometimes tumultuous relationship with Farrah. Michael's presence on the show has allowed audiences to gain insight into his role as a father, and has shed light on the complexities of their family dynamics.

Throughout his appearances on "Teen Mom," Michael has displayed a deep love and concern for his daughter, often offering guidance and emotional support during Farrah's most challenging moments. Their relationship has been marked by its ups and downs, but one thing that remains clear is Michael's unwavering dedication to his daughter's well-being. His role as a father has not only been to provide for his family financially, but also to offer emotional support and guidance through the various trials and tribulations that come with being a parent of a reality TV star.

Michael's commitment to his daughter's success is evident in his willingness to appear on the show and share their family's story with the world. Despite the often intense and emotional nature of their interactions on screen, Michael's love and concern for his daughter shines through, and his presence has added depth and dimension to the show. Viewers have been able to witness the highs and lows of their relationship, and Michael's open and honest communication style has made him a relatable and engaging character on the show.

In addition to his appearances on "Teen Mom," Michael has also been an advocate for mental health awareness and has used his platform to speak out about the importance of seeking help and support during difficult times. He has been open about his own struggles with mental health and has encouraged others to prioritize their well-being. Michael's willingness to share his personal experiences has resonated with many viewers, and has helped to destigmatize conversations around mental health.

Beyond his role as a supportive father and mental health advocate, Michael has also pursued other ventures outside of the reality TV world. He has dabbled in various business ventures, including real estate and property management, and has demonstrated a strong work ethic and determination to provide for his family. His drive and ambition have served as an inspiration to his daughter and others, and his entrepreneurial spirit has been a source of pride for the Abraham family.

In summary, Michael Abraham's presence on "Teen Mom" has allowed audiences to gain insight into the complexities of family dynamics and the challenges of parenting a reality TV star. His unwavering dedication to his daughter's well-being, his advocacy for mental health awareness, and his entrepreneurial spirit have made him a compelling and engaging figure both on and off screen. Michael's openness and honesty have resonated with viewers, and his role as a father has added depth and dimension to the show. His impact extends beyond the realm of reality TV, and his dedication to his family and his passions serves as an inspiration to many.

Michael Abraham's Email Addresses

Michael Abraham's Phone Numbers

People you may be

interested in

American baseball pitcher

French actor and model

American actor and director

American businesswoman and actress

Football running back

Journalist

American actress and model

American fencer

American singer-songwriter and actress

Actor

Actress

Spanish tennis player