Manoj Dhulashia's Email & Phone Number

Passionate, Success Strategist, Experienced IT Services, Solution and Product Sales & BD Person

Manoj Dhulashia Email Addresses

Manoj Dhulashia Phone Numbers

Manoj Dhulashia's Work Experience

Team Computers Pvt. Ltd.

Sr. Business Development Manager

January 2019 to Present

Team Computers Pvt. Ltd.

Business Development Manager

January 2019 to March 2020

Ensure Support Services Limited (Redington India Ltd.)

Business Development Manager

April 2017 to January 2019

Wipro Limited

Business Development Manager

October 2011 to March 2017

Sales Manager

CMS IT SERVICES Pvt. Ltd.

Sales Manager

Show more

Show less

Frequently Asked Questions about Manoj Dhulashia

What is Manoj Dhulashia phone number?

Manoj Dhulashia phone number is 8000877477.

How to contact Manoj Dhulashia?

If you want to call Manoj Dhulashia try calling on 8000877477.

What company does Manoj Dhulashia work for?

Manoj Dhulashia works for Team Computers Pvt. Ltd.

What is Manoj Dhulashia's role at Team Computers Pvt. Ltd.?

Manoj Dhulashia is Sr. Business Development Manager

What is Manoj Dhulashia's personal email address?

Manoj Dhulashia's personal email address is ma****[email protected]

What is Manoj Dhulashia's business email address?

Manoj Dhulashia's business email address is manoj.dhulashia@***.***

What industry does Manoj Dhulashia work in?

Manoj Dhulashia works in the Information Technology & Services industry.

Manoj Dhulashia Email Addresses

Manoj Dhulashia Phone Numbers

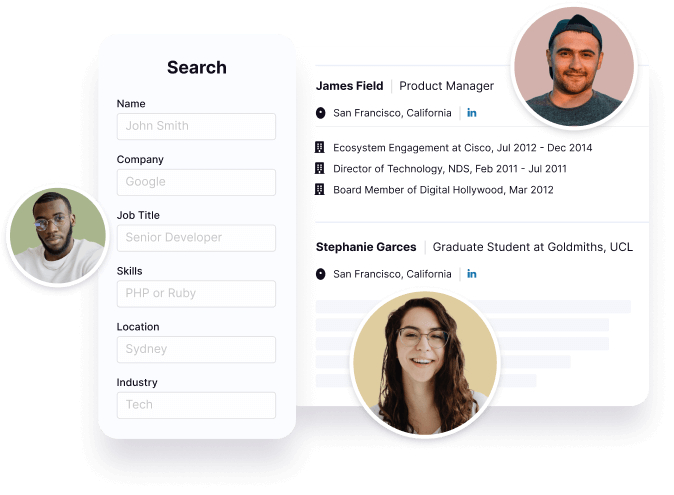

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Manoj Dhulashia's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Manoj Dhulashia's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 87% chance that Manoj Dhulashia is seeking for new opportunities

Manoj Dhulashia's Social Media Links

/in/manoj-dhulashia-197010139