Louise Adrina's Email & Phone Number

VP of Operations - Customer Care Unit at GO-JEK

Louise Adrina Email Addresses

Louise Adrina's Education

Universitas Katolik Parahyangan

January 2003 to January 2007

National Taiwan University of Science and Technology

January 2009 to January 2010

SMUK 1 BPK Penabur, Jakarta

January 2000 to January 2003

Show more

Show less

Frequently Asked Questions about Louise Adrina

What is Louise Adrina email address?

Email Louise Adrina at [email protected], [email protected] and [email protected]. This email is the most updated Louise Adrina's email found in 2024.

What is Louise Adrina phone number?

Louise Adrina phone number is +6281808006319.

How to contact Louise Adrina?

To contact Louise Adrina send an email to [email protected], [email protected] or [email protected]. If you want to call Louise Adrina try calling on +6281808006319.

What company does Louise Adrina work for?

Louise Adrina works for GOJEK

What is Louise Adrina's role at GOJEK?

Louise Adrina is Employee

What industry does Louise Adrina work in?

Louise Adrina works in the Financial Services industry.

Louise Adrina Email Addresses

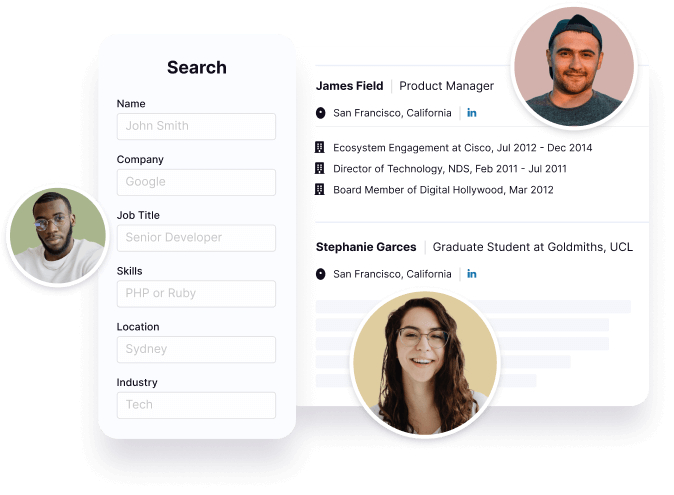

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Louise Adrina's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Louise Adrina's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 86% chance that Louise Adrina is seeking for new opportunities

Louise Adrina's Social Media Links

/in/louiseadrina