Cody Dodd's Email & Phone Number

Airbus AS350 Medical Transport Mechanic at Aeroproducts Component Services

Cody Dodd Email Addresses

Cody Dodd's Work Experience

aero products

component shop technician

March 2014 to Present

aeroproducts

hanger maintenance lead 206,407

November 2014 to Present

Aeroproducts Component Services

Airbus AS350 Medical Transport Mechanic

March 2017 to Present

overseas aircraft support

production lead

February 2012 to March 2014

overseas aircraft support

Flight line/Assembly Technician

May 2011 to March 2012

overseas aircraft support

component shop technician

September 2009 to May 2011

overseas aircraft support

Painter

February 2009 to September 2009

Tate's auto group

mechanic

September 2008 to February 2009

Show more

Show less

Cody Dodd's Education

Federal exams

Airframe and powerplant certificate, Mechanics, A

April 2024 to April 2024

chino valley high school

high school diploma

April 2024 to April 2024

Bell helicopter training academy 205 212 component overhaul training

April 2024 to April 2024

Bell Helicopter Training Academy

429 Avionics and Automatic Flight Control Systems, Avionics Maintenance Technology/Technician

April 2024 to April 2024

Bell helicopter training academy

222 230 430 component overhaul training, Mechanics and Repairers, General

April 2024 to April 2024

Yavapai College

Auto mechanics and painting, Mechanics and Repairers, General

April 2024 to April 2024

Show more

Show less

Frequently Asked Questions about Cody Dodd

What is cody dodd email address?

Email cody dodd at [email protected]. This email is the most updated cody dodd's email found in 2024.

How to contact cody dodd?

To contact cody dodd send an email to [email protected].

What company does Cody Dodd work for?

Cody Dodd works for Aeroproducts Component Services

What is Cody Dodd's role at Aeroproducts Component Services?

Cody Dodd is Airbus AS350 Medical Transport Mechanic

What is Cody Dodd's Phone Number?

Cody Dodd's phone (602) ***-*424

What industry does Cody Dodd work in?

Cody Dodd works in the Airlines/Aviation industry.

Cody Dodd's Professional Skills Radar Chart

Based on our findings, Cody Dodd is ...

What's on Cody Dodd's mind?

Based on our findings, Cody Dodd is ...

Cody Dodd's Estimated Salary Range

Cody Dodd Email Addresses

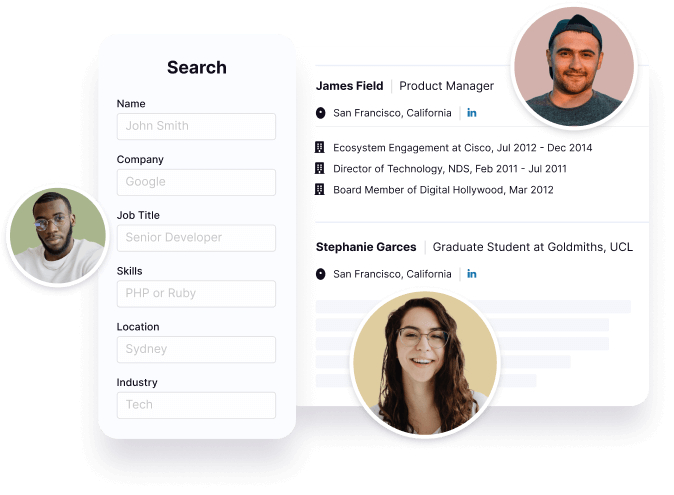

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Cody Dodd's Ranking

Ranked #147 out of 2,941 for Airbus AS350 Medical Transport Mechanic in Arizona

Cody Dodd's Personality Type

Introversion (I), Sensing (S), Thinking (T), Perceiving (P)

Average Tenure

2 year(s), 0 month(s)

Cody Dodd's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 87% chance that Cody Dodd is seeking for new opportunities

Cody Dodd's Social Media Links

/in/cody-dodd-80065590