Shailesh Kulkarni PMP, CSM's Email & Phone Number

President - Digital Product Engineering at e-Zest Solutions

Shailesh Kulkarni PMP, CSM Email Addresses

Shailesh Kulkarni PMP, CSM Phone Numbers

Shailesh Kulkarni PMP, CSM's Work Experience

Domain Systems

Software Engineer

October 2002 to February 2004

SvarSoft Pvt. Ltd.

Graduate Trainee Engineer (Software)

September 2000 to October 2002

President - Digital Product Engineering

Show more

Show less

Shailesh Kulkarni PMP, CSM's Education

Rajarambapu Institute of Technology, Rajaramnagar, SAKHARALE

January 1996 to January 1999

Indian School of Business

January 2021 to January 2021

Show more

Show less

Frequently Asked Questions about Shailesh Kulkarni PMP, CSM

What is Shailesh Kulkarni email address?

Email Shailesh Kulkarni at [email protected], [email protected] and [email protected]. This email is the most updated Shailesh Kulkarni's email found in 2024.

What is Shailesh Kulkarni phone number?

Shailesh Kulkarni phone number is 9822245024.

How to contact Shailesh Kulkarni?

To contact Shailesh Kulkarni send an email to [email protected], [email protected] or [email protected]. If you want to call Shailesh Kulkarni try calling on 9822245024.

What company does Shailesh Kulkarni PMP, CSM work for?

Shailesh Kulkarni PMP, CSM works for e-Zest Solutions

What is Shailesh Kulkarni PMP, CSM's role at e-Zest Solutions?

Shailesh Kulkarni PMP, CSM is Senior Software Engineering

What industry does Shailesh Kulkarni PMP, CSM work in?

Shailesh Kulkarni PMP, CSM works in the Information Technology & Services industry.

Shailesh Kulkarni PMP, CSM Email Addresses

Shailesh Kulkarni PMP, CSM Phone Numbers

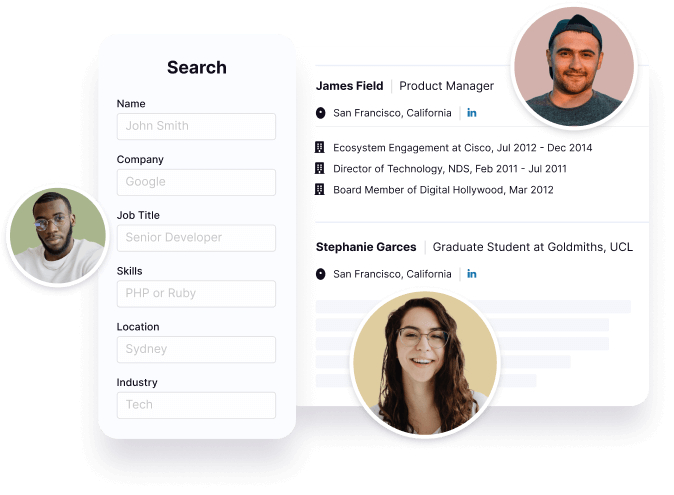

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Shailesh Kulkarni PMP, CSM's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Shailesh Kulkarni PMP, CSM's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 86% chance that Shailesh Kulkarni PMP, CSM is seeking for new opportunities

Shailesh Kulkarni PMP, CSM's Social Media Links

/in/shaileshkulkarnipmp