Tony Weisser's Email & Phone Number

President/Owner MTS, Inc. & Tony Weisser Engineering with Automation, Machine/Tool design, and Tool & Die expertise

Tony Weisser Email Addresses

Tony Weisser's Work Experience

Tony Weisser Engineering

President & Project/Design Engineer

Mesh Engineering

Senior Applications Engineer

Mechanical Technical Systems, Inc.

President/Owner Fully/Semi-Automated Systems

Mikron Assembly Technology

Project Engineer

Tampo Tool/TransTech America

Senior Project Engineer

Show more

Show less

Tony Weisser's Education

William Rainey Harper College (Non-Degreed)

Wheeling High School

Participated in an Engineering Diversified Occupations Program

Show more

Show less

Frequently Asked Questions about Tony Weisser

What is Tony Weisser email address?

Email Tony Weisser at [email protected]. This email is the most updated Tony Weisser's email found in 2024.

How to contact Tony Weisser?

To contact Tony Weisser send an email to [email protected].

What company does Tony Weisser work for?

Tony Weisser works for Tony Weisser Engineering

What is Tony Weisser's role at Tony Weisser Engineering?

Tony Weisser is President & Project/Design Engineer

What is Tony Weisser's Phone Number?

Tony Weisser's phone (**) *** *** 327

What industry does Tony Weisser work in?

Tony Weisser works in the Mechanical or Industrial Engineering industry.

Tony Weisser's Professional Skills Radar Chart

Based on our findings, Tony Weisser is ...

What's on Tony Weisser's mind?

Based on our findings, Tony Weisser is ...

Tony Weisser's Estimated Salary Range

Tony Weisser Email Addresses

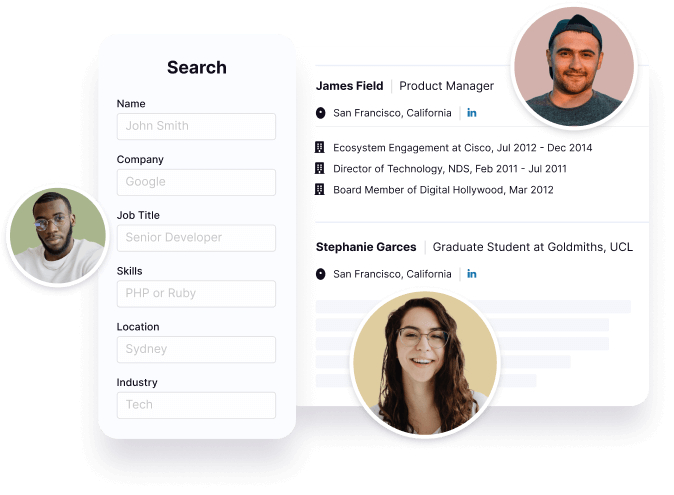

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Tony Weisser's Personality Type

Introversion (I), Intuition (N), Thinking (T), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Tony Weisser's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 88% chance that Tony Weisser is seeking for new opportunities

Top Searched People

Elvis Presley's brother

American stock trader

Singer ‧ Eddie Money's daughter

American musician

YouTuber

Tony Weisser's Social Media Links

/in/tony-h-weisser-88654436