Sarah Button's Email & Phone Number

Product Specialist - Nitro Technologies

Sarah Button's Email Addresses

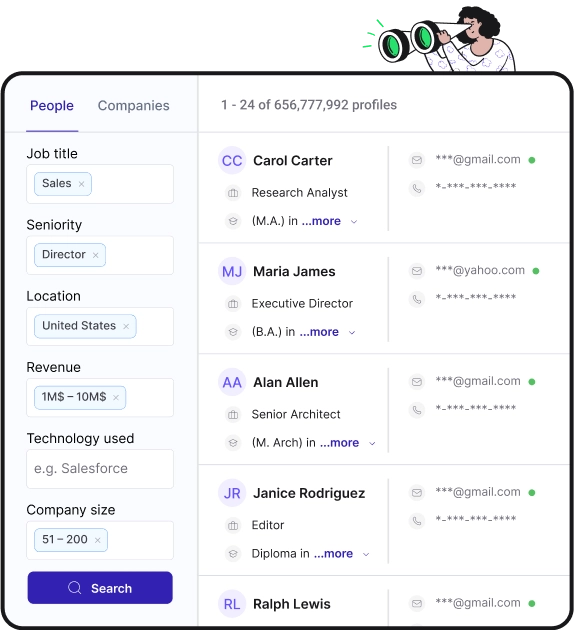

Find personal and work emails for over 300M professionals

Not the Sarah Button you were looking for? Continue your search below:About Sarah Button

📖 Summary

Sarah Button is a dedicated Product Specialist at Nitro Technologies, where she leverages her expertise to drive product development and innovation. With a deep understanding of customer needs and industry trends, Sarah plays a pivotal role in identifying opportunities for product improvements and new feature development. Her passion for technology and commitment to delivering exceptional user experiences make her a valuable asset to the Nitro team.

As a Product Specialist, Sarah is responsible for gathering and analyzing customer feedback, market research, and competitive analysis to inform product decisions. She collaborates with cross-functional teams to translate these insights into actionable strategies that drive product innovation and customer satisfaction. By closely monitoring industry trends and staying informed about emerging technologies, Sarah ensures that Nitro's products remain at the forefront of innovation.

Sarah's strong technical background and excellent communication skills enable her to effectively bridge the gap between customers, developers, and other internal stakeholders. She is adept at articulating the needs of the customer and synthesizing complex technical information into clear product requirements. By championing the voice of the customer, Sarah ensures that Nitro's product roadmap is aligned with market demands and customer expectations.

One of Sarah's key strengths is her ability to prioritize product features and enhancements based on their potential impact on the customer experience and business goals. She collaborates with the engineering and design teams to ensure that the product roadmap aligns with technical capabilities and resource constraints. Her strategic approach to product development has been instrumental in driving the successful launch of new products and the continuous improvement of existing ones.

In addition to her day-to-day responsibilities, Sarah is an advocate for customer-centric product development and a mentor to junior members of the product team. She actively promotes a culture of innovation and excellence within the organization, encouraging her colleagues to think creatively and strive for excellence in their work. Her leadership and mentorship have helped cultivate a high-performing product team that is dedicated to delivering best-in-class solutions to customers.

Overall, Sarah Button is a highly skilled and passionate Product Specialist who is committed to driving product excellence and customer satisfaction at Nitro Technologies. Her in-depth knowledge of technology, market dynamics, and customer needs, combined with her effective communication and leadership skills, make her a valuable asset to the organization. Through her strategic product insights and collaborative approach, Sarah continues to play a pivotal role in shaping Nitro's product portfolio and driving the company's success in the competitive tech industry.

Sarah Button's Email Addresses

People you may be

interested in

Romanian-American actor

Canadian actress

American musician and singer-songwriter

American songwriter and record producer

Swiss ice hockey winger

YouTuber

American actress

English actor and singer

American professional cook

CEO of Twitter

American actress and comedian

Writer and comedian