Michelle Nguyen's Email & Phone Number

Gastroenterologist in Los Gatos, California

Michelle Nguyen's Email Addresses

Michelle Nguyen's Phone Numbers

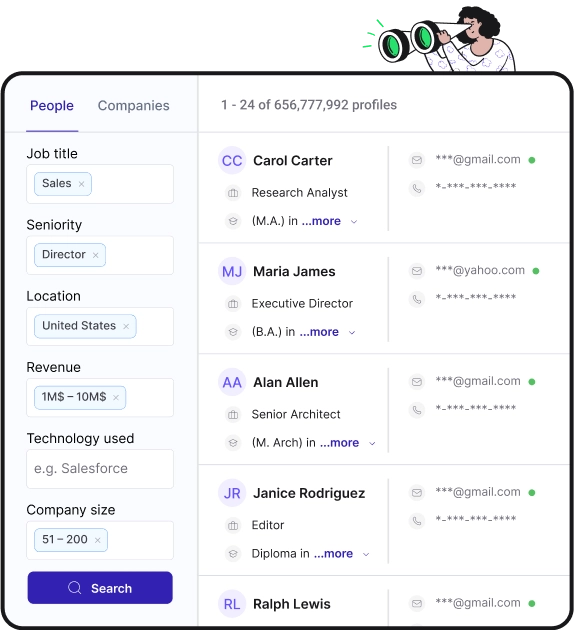

Find personal and work emails for over 300M professionals

Not the Michelle Nguyen you were looking for? Continue your search below:About Michelle Nguyen

📖 Summary

Michelle Nguyen is a highly respected and experienced gastroenterologist practicing in Los Gatos, California. With a passion for helping her patients achieve optimal digestive health, Dr. Nguyen is dedicated to providing comprehensive care and personalized treatment plans for a wide range of gastrointestinal conditions.

Dr. Nguyen completed her medical education at the prestigious Stanford University School of Medicine, where she excelled in her studies and clinical training. Following medical school, she pursued a residency in internal medicine at Stanford Hospital, where she honed her skills in the diagnosis and management of complex medical conditions. She then went on to complete a fellowship in gastroenterology at the University of California, San Francisco, where she gained specialized expertise in the treatment of digestive disorders.

As a board-certified gastroenterologist, Dr. Nguyen is well-equipped to diagnose and treat a variety of gastrointestinal conditions, including inflammatory bowel disease, irritable bowel syndrome, acid reflux, and liver diseases. She is also skilled in performing a range of endoscopic procedures, such as colonoscopies and upper endoscopies, to evaluate and treat digestive issues. With her extensive training and experience, Dr. Nguyen is able to provide thorough and accurate diagnoses, as well as innovative and effective treatment options for her patients.

Dr. Nguyen is known for her compassionate and patient-centered approach to care, taking the time to listen to her patients' concerns and providing them with the information and support they need to make informed decisions about their health. She understands that digestive health issues can have a significant impact on a person's quality of life, and she is dedicated to helping her patients achieve long-term relief and improved well-being.

In addition to her clinical practice, Dr. Nguyen is actively involved in research and education in the field of gastroenterology. She has published numerous articles in medical journals and has presented her research at national and international conferences. She is also committed to staying up-to-date on the latest advancements in her field, regularly attending professional development courses and conferences to ensure that she is able to provide the most advanced and effective care for her patients.

Dr. Nguyen is a valued member of the medical community in Los Gatos, California, and is dedicated to serving the diverse needs of her patients. She is fluent in English, Spanish, and Vietnamese, which allows her to effectively communicate with a broad range of patients from different cultural backgrounds. Her ability to connect with her patients and provide care in their preferred language is just one of the many ways she demonstrates her commitment to delivering personalized and patient-centered care.

In her spare time, Dr. Nguyen enjoys staying active and healthy, and she encourages her patients to do the same. She is an avid runner, hiker, and yoga enthusiast, and she believes that maintaining a healthy lifestyle is an important part of managing digestive health. She also volunteers her time to provide medical care to underserved communities, both locally and abroad, and is passionate about giving back and making a positive impact in the world.

Overall, Dr. Michelle Nguyen is an exceptional gastroenterologist who is dedicated to providing comprehensive and compassionate care to her patients. With her expertise, empathy, and commitment to excellence, she is a trusted partner in helping her patients achieve and maintain optimal digestive health. If you are in need of a knowledgeable and caring gastroenterologist in Los Gatos, California, Dr. Nguyen is an outstanding choice.

Michelle Nguyen's Email Addresses

Michelle Nguyen's Phone Numbers

People you may be

interested in

Journalist

Filipino actress

American singer and songwriter

American actor

Nigerian singer and rapper

Filipino actress and television host

American singer and songwriter

Italian comedian and film actor

American professional wrestler

American comedian and actress

Drummer

TV personality