Mark Simmons's Email & Phone Number

Comedian

Mark Simmons's Email Addresses

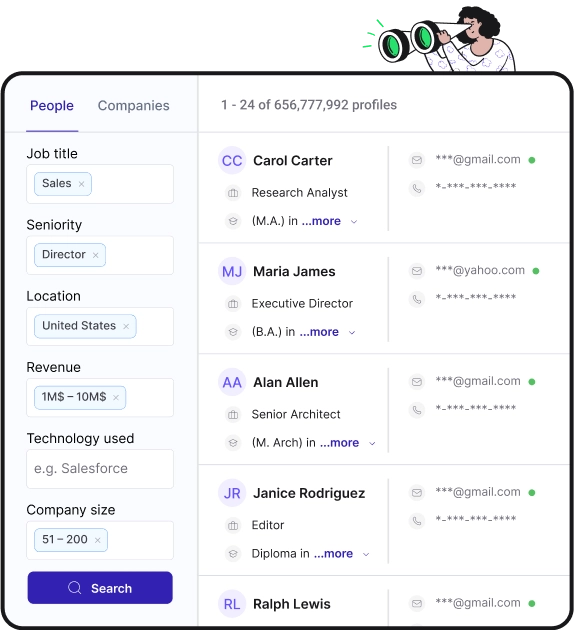

Find personal and work emails for over 300M professionals

Not the Mark Simmons you were looking for? Continue your search below:About Mark Simmons

📖 Summary

Mark Simmons is a comedian known for his sharp wit, clever wordplay, and irreverent takes on contemporary culture. With a deadpan delivery and a knack for finding humor in the mundane, Mark has established himself as a rising star in the UK comedy scene.

Hailing from Dorking, Surrey, Mark's unique brand of comedy has earned him a loyal following and critical acclaim. His observational humor and clever one-liners have made him a hit on the comedy club circuit, as well as on television and radio.

Mark's comedy is often described as smart, dry, and sometimes darkly humorous. He has a way of twisting everyday situations into something absurd and hilarious, and his ability to find the humor in life's absurdities has endeared him to audiences of all ages.

One of Mark's trademarks is his quick-fire delivery, which keeps audiences on their toes and ensures that no one knows what to expect next. His ability to seamlessly weave together puns, jokes, and stories is a testament to his skill as a wordsmith and a storyteller.

Mark's comedy has been described as "incredibly clever" and "hilariously deadpan" by critics, and his performances are often lauded for their originality and unpredictability. With a keen eye for the absurd and a knack for finding humor in the most unexpected places, Mark has carved out a niche for himself in the world of stand-up comedy.

In addition to his live performances, Mark has also made a name for himself on the small screen. He has appeared on several popular comedy panel shows, such as Mock the Week and The Stand Up Show, where his quick wit and sharp sense of humor have made him a standout performer.

Mark has also established himself as a regular on the UK comedy festival circuit, performing at prestigious events such as the Edinburgh Festival Fringe and the Leicester Comedy Festival. His live shows are always a hit with audiences, and he has received rave reviews for his performances at some of the biggest comedy festivals in the country.

In recent years, Mark has also made a name for himself on the radio, with appearances on shows such as The Now Show and The News Quiz. His sharp, incisive commentary on the world around him has made him a popular guest on comedy panel shows and radio programs, and he has garnered a loyal following for his no-nonsense approach to comedy.

As a comedian, Mark Simmons is known for his dry wit, clever wordplay, and keen observations of everyday life. His ability to find humor in the most unexpected places and his razor-sharp delivery have made him a standout performer on the UK comedy circuit. With a growing list of accolades and a loyal fanbase, Mark is definitely a comedian to watch in the coming years. If you're looking for a comedian who will leave you in stitches with his clever one-liners and witty observations, look no further than Mark Simmons.

Mark Simmons's Email Addresses

People you may be

interested in

43rd U.S. President

American actress

American singer-songwriter

Actor

English actor

United States Representative

English actor and singer

Dancer

American actress

Actor

Dynamics 365 Business Central Consultant | Navision | ERP | Business Analyst | Director at Memorli Business Solutions

Speaker and Consultant