Madjid Farmahini-Farahani's Email & Phone Number

Chemical/Polymer Engineer, EIT

Madjid Farmahini-Farahani Email Addresses

Madjid Farmahini-Farahani Phone Numbers

Madjid Farmahini-Farahani's Work Experience

Graduate Research Assistant

SAIPA (Citroëns, Iran)

Polymer/Quality assurance engineer

Kousha Metal Industries Co.

Process Engineer and Polymer Lab Supervisor and member of R&D

Show more

Show less

Madjid Farmahini-Farahani's Education

University of New Brunswick

Doctor of Philosophy (Ph.D.) Chemical Engineering

University of Tehran

Master of Science (MSc) Polymer/Plastics Engineering

Isfahan University of Technology

Bachelor's degree Chemical Engineering – Polymer industry

Show more

Show less

Frequently Asked Questions about Madjid Farmahini-Farahani

What is Madjid Farmahini-Farahani email address?

Email Madjid Farmahini-Farahani at [email protected] and [email protected]. This email is the most updated Madjid Farmahini-Farahani's email found in 2024.

What is Madjid Farmahini-Farahani phone number?

Madjid Farmahini-Farahani phone number is +15064718989.

How to contact Madjid Farmahini-Farahani?

To contact Madjid Farmahini-Farahani send an email to [email protected] or [email protected]. If you want to call Madjid Farmahini-Farahani try calling on +15064718989.

What company does Madjid Farmahini-Farahani work for?

Madjid Farmahini-Farahani works for University of New Brunswick

What is Madjid Farmahini-Farahani's role at University of New Brunswick?

Madjid Farmahini-Farahani is Graduate Research Assistant

What industry does Madjid Farmahini-Farahani work in?

Madjid Farmahini-Farahani works in the Higher Education industry.

Madjid Farmahini-Farahani's Professional Skills Radar Chart

Based on our findings, Madjid Farmahini-Farahani is ...

What's on Madjid Farmahini-Farahani's mind?

Based on our findings, Madjid Farmahini-Farahani is ...

Madjid Farmahini-Farahani's Estimated Salary Range

Madjid Farmahini-Farahani Email Addresses

Madjid Farmahini-Farahani Phone Numbers

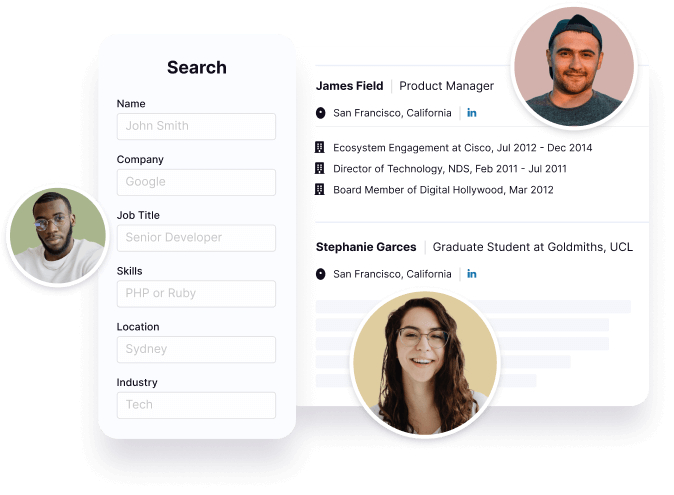

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Madjid Farmahini-Farahani's Personality Type

Introversion (I), Sensing (S), Thinking (T), Perceiving (P)

Average Tenure

2 year(s), 0 month(s)

Madjid Farmahini-Farahani's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 100% chance that Madjid Farmahini-Farahani is seeking for new opportunities

Top Searched People

American internet personality

Former chief technology officer of YouTube

American actress

American author

American actress

Madjid Farmahini-Farahani's Social Media Links

/in/madjid-farmahini-farahani-08633740 scholar.google.ca