Vignesh C's Email & Phone Number

Technical Recruiter | Technology Hiring @ Freshworks Inc. (formerly Freshdesk).We're hiring -Backend Engineers , SDET /SET , Frontend Engineers.

Vignesh C Email Addresses

Vignesh C's Work Experience

Covenant Consultants

Talent Acquisition Specialist

May 2016 to March 2020

Talent sourcer

Talent Acquisition Specialist

Show more

Show less

Vignesh C's Education

Loyola -pondicherry University

January 2016 to January 2018

Anna university

January 2011 to January 2015

Show more

Show less

Frequently Asked Questions about Vignesh C

What is Vignesh C email address?

Email Vignesh C at [email protected]. This email is the most updated Vignesh C's email found in 2024.

How to contact Vignesh C?

To contact Vignesh C send an email to [email protected].

What company does Vignesh C work for?

Vignesh C works for Freshworks

What is Vignesh C's role at Freshworks?

Vignesh C is Talent sourcer

What is Vignesh C's Phone Number?

Vignesh C's phone (**) *** *** 319

What industry does Vignesh C work in?

Vignesh C works in the Information Technology & Services industry.

Vignesh C Email Addresses

Find emails and phone numbers for 300M professionals.

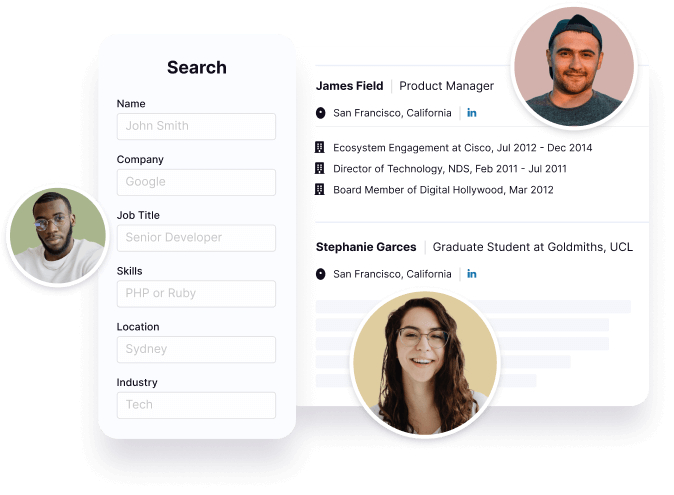

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Vignesh C's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Vignesh C's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 89% chance that Vignesh C is seeking for new opportunities

Vignesh C's Social Media Links

/in/talentrooter