Dr.Yogesh Prabhakaran's Email & Phone Number

Founder - Director at Thriphala Ayurveda & Spa Consultancy -

Dr.Yogesh Prabhakaran Email Addresses

Dr.Yogesh Prabhakaran Phone Numbers

Dr.Yogesh Prabhakaran's Work Experience

Thriphala Ayurveda & Spa Consultancy

Founder - Director

January 2018 to Present

CORE Wellness Ltd. (Sohum Spa)

Vice President - Operations Sohum Spa

February 2011 to January 2018

Group Ayurveda Doctor -The Oberoi Group & Spa Manager- The Oberoi Udaivilas Udaipur

May 2006 to August 2010

Thriphala Ayurveda & Spa Consultancy

Director

March 2005 to April 2006

Show more

Show less

Dr.Yogesh Prabhakaran's Education

Govt. Ayurveda College Tripunithura -Mahatma Gandhi University Kottayam -Kerala

January 1989 to January 1995

Mahatma Gandhi University

January 1989 to January 1995

Show more

Show less

Frequently Asked Questions about Dr.Yogesh Prabhakaran

What is Dryogesh Prabhakaran email address?

Email Dryogesh Prabhakaran at [email protected]. This email is the most updated Dryogesh Prabhakaran's email found in 2024.

How to contact Dryogesh Prabhakaran?

To contact Dryogesh Prabhakaran send an email to [email protected].

What company does Dr.Yogesh Prabhakaran work for?

Dr.Yogesh Prabhakaran works for Thriphala Ayurveda & Spa Consultancy

What is Dr.Yogesh Prabhakaran's role at Thriphala Ayurveda & Spa Consultancy?

Dr.Yogesh Prabhakaran is Director

What is Dr.Yogesh Prabhakaran's Phone Number?

Dr.Yogesh Prabhakaran's phone (**) *** *** 363

What industry does Dr.Yogesh Prabhakaran work in?

Dr.Yogesh Prabhakaran works in the Hospitality industry.

Dr.Yogesh Prabhakaran Email Addresses

Dr.Yogesh Prabhakaran Phone Numbers

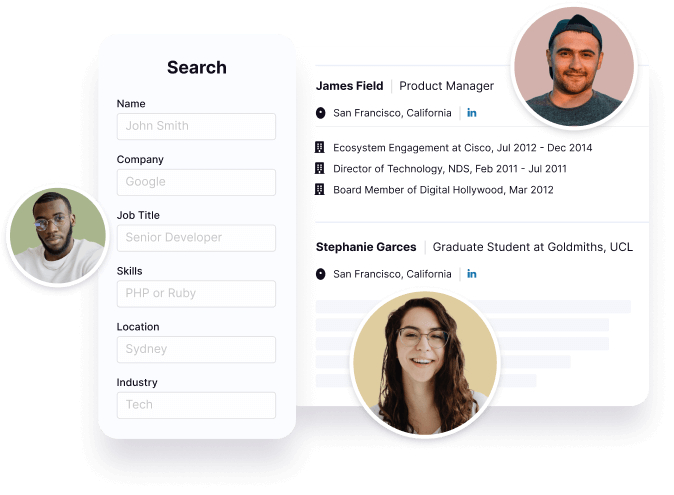

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Dr.Yogesh Prabhakaran's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Dr.Yogesh Prabhakaran's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 76% chance that Dr.Yogesh Prabhakaran is seeking for new opportunities

Dr.Yogesh Prabhakaran's Social Media Links

/in/dr-yogesh-prabhakaran-02408114