Bobbi Chadwick's Email & Phone Number

Director, Corporate Procurement at WinCup

Bobbi Chadwick Email Addresses

Bobbi Chadwick's Work Experience

RockTenn Company

Director, Capital Procurement

August 2011 to August 2015

RockTenn Company

Senior Procurement Manager, Mill Capital

August 2011 to July 2014

AGL Resources

Manager Strategic Initiatives

June 2009 to August 2011

AT Kearney

E-Sourcing Manager

September 2004 to August 2005

RockTenn Company

Purchasing and Analysis - Folding Carton Division

October 2001 to September 2003

Union Camp Corporation

Recycled Fibers Buyer

June 1994 to January 2000

Show more

Show less

Bobbi Chadwick's Education

Liberty University

Show more

Show less

Frequently Asked Questions about Bobbi Chadwick

What is Bobbi Chadwick email address?

Email Bobbi Chadwick at [email protected] and [email protected]. This email is the most updated Bobbi Chadwick's email found in 2024.

How to contact Bobbi Chadwick?

To contact Bobbi Chadwick send an email to [email protected] or [email protected].

What company does Bobbi Chadwick work for?

Bobbi Chadwick works for WinCup

What is Bobbi Chadwick's role at WinCup?

Bobbi Chadwick is Corporate Procurement

What is Bobbi Chadwick's Phone Number?

Bobbi Chadwick's phone (404) ***-*179

What industry does Bobbi Chadwick work in?

Bobbi Chadwick works in the Food & Beverages industry.

Bobbi Chadwick's Professional Skills Radar Chart

Based on our findings, Bobbi Chadwick is ...

What's on Bobbi Chadwick's mind?

Based on our findings, Bobbi Chadwick is ...

Bobbi Chadwick's Estimated Salary Range

Bobbi Chadwick Email Addresses

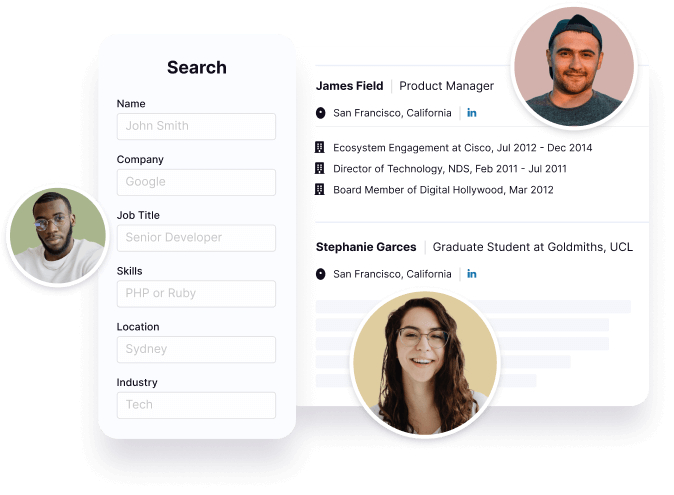

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Bobbi Chadwick's Ranking

Ranked #264 out of 5,272 for Corporate Procurement in Georgia

Bobbi Chadwick's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Bobbi Chadwick's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 88% chance that Bobbi Chadwick is seeking for new opportunities

Bobbi Chadwick's Social Media Links

/in/bobbichadwick /school/liberty-university/ /company/purafil-inc.