Konstantin Гонтмахер's Email & Phone Number

Маркетинг лояльности и CRM

Konstantin Гонтмахер Email Addresses

Konstantin Гонтмахер Phone Numbers

Konstantin Гонтмахер's Work Experience

July Tech

Генеральный директор

January 2019 to Present

ИЮЛЬ

Основатель

January 2009 to Present

SeriaSystem

Partner

January 2012 to January 2014

Halva Loyalty

CEO

January 2013 to January 2014

Центр Финансовых Технологий

Директор розничного направления

January 2007 to January 2009

ЗАО "ТД "Перекрёсток"

Руководитель проектов

January 2005 to January 2007

Система менеджмент

Партнёр

January 2005 to January 2006

ООО "Маркон"

Руководитель отдела новых технологий

January 2002 to January 2004

АНО "Биофармед"

Руководитель финансово-экономического отдела

January 2004 to January 2004

ОКБ "Сухого"

Техник

January 1998 to January 2000

Show more

Show less

Frequently Asked Questions about Konstantin Гонтмахер

What is Konstantin Gontmakher email address?

Email Konstantin Gontmakher at [email protected]. This email is the most updated Konstantin Gontmakher's email found in 2024.

What is Konstantin Gontmakher phone number?

Konstantin Gontmakher phone number is +7.4999517974.

How to contact Konstantin Gontmakher?

To contact Konstantin Gontmakher send an email to [email protected]. If you want to call Konstantin Gontmakher try calling on +7.4999517974.

What company does Konstantin Гонтмахер work for?

Konstantin Гонтмахер works for ИЮЛЬ

What is Konstantin Гонтмахер's role at ИЮЛЬ?

Konstantin Гонтмахер is Основатель

What industry does Konstantin Гонтмахер work in?

Konstantin Гонтмахер works in the Marketing & Advertising industry.

Konstantin Гонтмахер Email Addresses

Konstantin Гонтмахер Phone Numbers

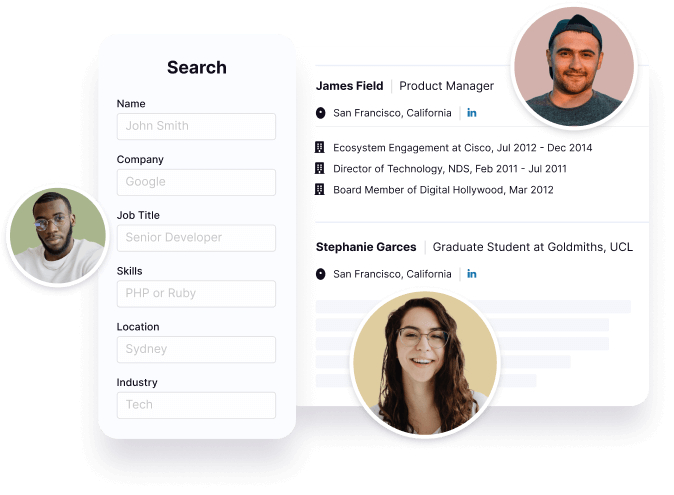

Find emails and phone numbers for 300M professionals.

Search by name, job titles, seniority, skills, location, company name, industry, company size, revenue, and other 20+ data points to reach the right people you need. Get triple-verified contact details in one-click.In a nutshell

Konstantin Гонтмахер's Personality Type

Extraversion (E), Intuition (N), Feeling (F), Judging (J)

Average Tenure

2 year(s), 0 month(s)

Konstantin Гонтмахер's Willingness to Change Jobs

Unlikely

Likely

Open to opportunity?

There's 93% chance that Konstantin Гонтмахер is seeking for new opportunities

Konstantin Гонтмахер's Social Media Links

/in/gontmakher